- Knowing what the customer wants.

- Knowing who the customer is.

- Getting customer focus in all parts of the organisation.

Other survey participants talk about the issue with knowing your customer when you work in a large organisation and never meet the end customer. This is the case for all kind of back office and support functions like IT, Finance, HR and Procurement for example. In most cases the customer is defined as the internal customer who receives the service provided. But can you be sure that you are producing what the end customer wants just because you provides exactly the service that the internal customer demands ? My personal experience is that it is not the case. Some IT systems and monthly financial reports would never have been implemented should the full life cycle cost be transparent and transferred to the internal customer making the demand.

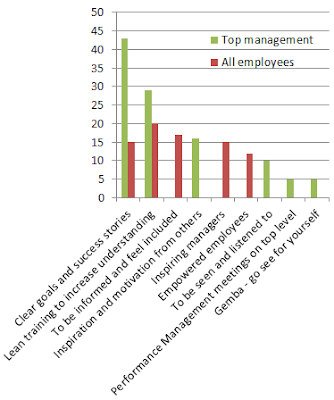

So, what are the main success factors for creating focus and attention on the end customer? The survey participants suggest many prerequisites and activities to achieve this.

|

| Key success factors to get focus on the external customer. |

Communication about the end customer and their need in all parts of an organisation is key to get focus. Many also suggest that Value Stream Mapping should be used to visualize for all employees how they create value and where they are in the value chain. Securing good (SMART) measures that are relevant for the end customer and visualise these for the whole organisation is also very important.

Seven respondents suggest that involving and cooperating more with the end customer is critical. Interesting enough that is only about half of the number of respondents who said that knowing what the end customer need is a major challenge.

It is not controversial to say that almost all companies and organisations can become more competitive or provide better service to their citizens if they increase their understanding of their customers need and stop doing things that don't contribute to satisfying that need. But fairly mature, customer centric companies still have large parts of their support functions not knowing which activities in a process create end custmer value or not. And the public sector, often put under pressure to give better service for less, don't always know who the customers are and even less what they want. How can you then get the entire organisaition focused on the end customer then?

Based on my personal experience as a Manager in back-office and support functions I think that a good start is often to visualize how much time is needed for each activity. When the cost becomes transparent it is easier to question non-value adding work and to allocate the cost to the right part of the organisation. If no Business Unit or Department wants to carry the production cost it probably means that the end customer doesn't want to pay for it either...

Follow and contribute to the discussion on LinkedIn:

http://www.linkedin.com/groups/What-are-main-challenges-key-1816278.S.58234251?qid=e0261008-3a91-49b1-abaf-5f066e419c71&trk=group_most_popular-0-b-ttl&goback=%2Egmp_1816278

Follow and contribute to the discussion on LinkedIn:

http://www.linkedin.com/groups/What-are-main-challenges-key-1816278.S.58234251?qid=e0261008-3a91-49b1-abaf-5f066e419c71&trk=group_most_popular-0-b-ttl&goback=%2Egmp_1816278